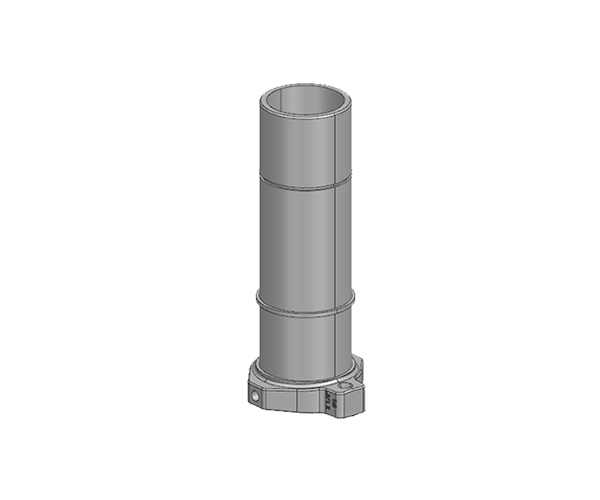

Aluminium Castings

Precision-designed Casting Solutions for Electrical Switchgear Applications

We have proven expertise in delivering premium-quality aluminium castings tailored for the electrical switchgear industry. Our advanced casting techniques and commitment to excellence ensure components that offer superior performance, durability, and reliability.Discover The NIPHA Edge

Advanced Aluminium Casting Techniques

- Precision Engineering

Utilising state-of-the-art casting methods, we produce aluminium components with intricate geometries and tight tolerances, ensuring exceptional quality and performance. - Material Excellence

Our expertise in aluminium alloys allows us to cater to diverse application requirements, providing solutions that are both lightweight and robust.

Scalable Production Capacity

- Robust Manufacturing Capability

With a monthly production capacity of 100 tons, currently operating at 60 tons, we efficiently manage high-volume orders while maintaining consistent quality. - Flexible Weight Range

Our castings range from lightweight components to larger structures, accommodating a wide spectrum of industrial needs.

Customisable Solutions

- Tailored to Specifications

We collaborate closely with clients to develop aluminium castings that meet specific requirements, ensuring each component aligns with precise operational demands. - Versatile Applications

Our aluminium castings are designed for various applications within the electrical switchgear industry, offering versatility and adaptability. - Stringent Quality Control & Durability

Comprehensive Testing:

Each casting undergoes rigorous quality assessments to ensure it meets international standards for performance and safety.

Enhanced Longevity:

Through meticulous manufacturing processes, our aluminium castings are built to withstand demanding environments, providing long-lasting service.

Further Processing & Surface Treatments

Tin Plating

Improves solderability and provides corrosion resistance.

Zinc Plating

Offers protection against rust and enhances surface strength.

Silver Plating

Ensures superior electrical conductivity, ideal for switchgear applications.

E-Coating

Provides uniform coverage with enhanced resistance to wear and corrosion.

Teflon Coating

Enhances friction resistance and improves operational efficiency.

Geomet Coating®

Offers exceptional corrosion resistance without heavy metals.

Hard Chrome Plating

Increases hardness, wear resistance, and surface durability.

Why Choose NIPHA?

-

Quality Assurance:

We ensure superior precision and durability through rigorous testing and expert craftsmanship.

-

Innovative Solutions:

We pioneer cutting-edge technologies to meet evolving industry demands with unmatched expertise.

-

Industry Leadership:

With decades of experience, we continuously set benchmarks in quality, performance, and reliability.

-

Efficiency Across Industries:

Our commitment to excellence ensures products that deliver value across diverse applications.

-

Customer-Centric Approach:

We prioritise client satisfaction with tailored solutions and responsive support services.

-

Continuous Improvement:

We embrace innovation and refinement to consistently exceed customer expectations.

Related Divisions

Our specialised divisions collaborate seamlessly to deliver precision-engineered aluminium castings.

Let’s Power the Future Together

Partner with NIPHA for aluminium castings that deliver precision, reliability, and performance. Contact us today to discuss your custom casting requirements.